STAS/SR S12Mn1.5Mo Enquiry | Print this page

| Category | Type | Steel grade | Standard | Country |

|---|---|---|---|---|

| Grades | Special Alloy | S12Mn1.5Mo | STAS/SR | Romania |

Chemical composition % of the ladle analysis of grade S12Mn1.5Mo

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) |

|---|---|---|---|---|---|---|---|

| 0.12 | 0.10-0.30 | 1.30-1.70 | 0.015 | 0.015 | Max 0.30 | 1.40-1.70 | 0.35-0.65 |

| Proof strength Rp0.2 (MPa) |

Tensile strength Rm (MPa) |

Impact energy KV (J) |

Elongation at fracture A (%) |

Reduction in cross section on fracture Z (%) |

As-Heat-Treated Condition | Brinell hardness (HBW) |

|---|---|---|---|---|---|---|

| 954 (≥) | 976 (≥) | 13 | 33 | 22 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 132 |

| Property | Density kg/dm3 |

Temperature T °C/F |

Specific heat J / kgK |

Thermal conductivity W/mK |

Electric resistance µΩ·cm |

Modulus of elasticity kN/mm2 |

Expansion rate |

|---|---|---|---|---|---|---|---|

| 571 (≥) | 379 (≥) | 24 | 34 | 12 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 241 | |

| Temp. °C/°F |

Creep strain limit (10000h) (Rp1,0) N/mm2 |

Creep rupture strength (10000h) (Rp1,0) N/mm2 |

|||||

| 157 | 886 | 825 |

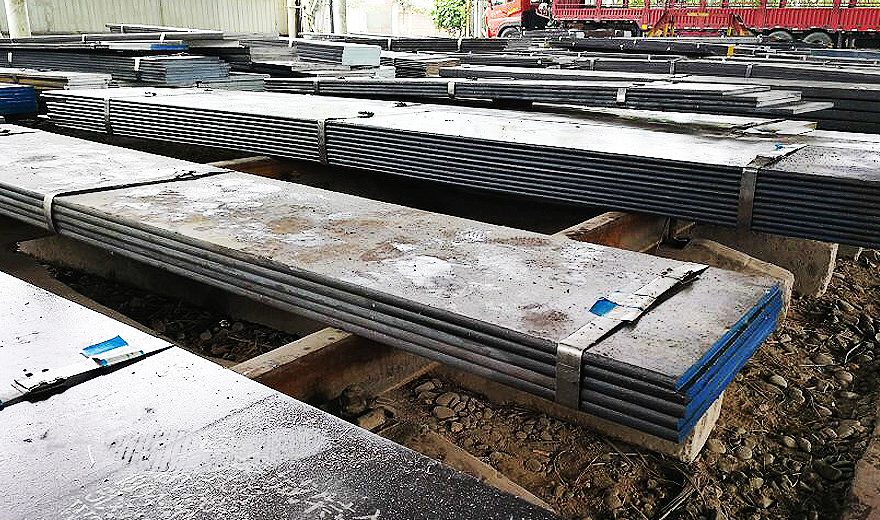

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

| Grade | Standard | Country | Application |

|---|---|---|---|

| 1Cr18Mn10Ni5Mo3N | STAS/SR | Romania | Of urea with good corrosion resistance, can produce urea corrosion of the equipment. |

| 0Cr26Ni5Mo2 | STAS/SR | Romania | Seamless stainless steel tubes for boiler and heat exchanger |

| 00Cr18Ni5Mo3Si2 | STAS/SR | Romania | Stainless steel bars |

| 1Cr5Mo | STAS/SR | Romania | Seamless steel tubes for high-pressure chemical fertilizer equipments |

| 2.4668 | STAS/SR | Romania | Classification and designation for superalloys and high temperature intermetallic materials |

| NiCr19Fe19Nb5Mo3 | STAS/SR | Romania | Classification and designation for superalloys and high temperature intermetallic materials |

| A 1014 N07718 | STAS/SR | Romania | Standard Specification for Precipitation-Hardening Bolting (UNS N07718) for High Temperature Service |

| B 637 N07718 | STAS/SR | Romania | Precipitation-Hardening and Cold Worked Nickel Alloy Bars, Forgings, and Forging Stock for Moderate or High Temperature Service |

| B 670 N07718 | STAS/SR | Romania | Precipitation-Hardening Nickel Alloy (UNS N07718) Plate, Sheet, and Strip for High-Temperature Service |

| B 983 N07718 | STAS/SR | Romania | Precipitation Hardened or Cold Worked, Seamless Nickel Alloy Pipe and Tube |

| N07718 | STAS/SR | Romania | Ni-Cr Alloy Precipitation Hardenable |

| Inconel 718 | STAS/SR | Romania | Nickel Alloy, Corrosion and Heat-Resistant, Seamless Tubing 52.5Ni - 19Cr - 3.0Mo - 5.1Cb (Nb) - 0.90Ti - 0.50Al - 18Fe Consumable Electrode Remelted or Vacuum Induction Melted 1775°F (968°C) Solution Heat Treated |

| Inconel 718 | STAS/SR | Romania | Nickel Alloy, Corrosion and Heat-Resistant, Seamless Tubing 52.5Ni - 19Cr - 3.0Mo - 5.1Cb (Nb) - 0.90Ti - 0.50Al - 18Fe Consumable Electrode Remelted or Vacuum Induction Melted 1775°F (968°C) Solution Heat Treated |