4Cr14Ni14W2Mo to join a large number of Cr, Ni elements in steel is mainly in order to obtain the austenitic organization at room temperature, and improve the corrosion resistance and oxidation resistance of steel.The other elements of Cr, Ni solid dissolved in austenitic austenitic organization to solid solution strengthening.

4Cr14Ni14W2Mo join W, Mo element in steel is mainly in order to form carbide, take the C elements in steel, avoid C element and element Cr form carbides and reduce the Cr element content, so as to improve the electrode potential of steel, steel corrosion resistance and oxidation resistance.High temperature solid solution treatment is not soluble in W, Mo element of carbides in the grain boundary pinning effect, can prevent the austenitic grain size grew up, have the effect of refining grain, can contribute to the improvement of the tenacity of steel.Solid solution treatment, all elements of Cr, Ni and a small amount of W, Mo elements dissolve in austenite, solid solution strengthening austenite.W, Mo element when high temperature aging treatment of carbide precipitation from austenite and a small amount of Cr element of carbide precipitation from austenite, also with not dissolve of W, Mo, elements of the carbide, improve the strength, hardness and wear resistance of steel.

As W, Mo element of carbide precipitation from austenite, need high temperature heating and experience a longer time of heat preservation, so the 4Cr14Ni14W2Mo steel has high thermal stability.Under 650 ℃ has the good mechanical properties.During 600 ~ 800 ℃, easy for strongly reinforced by aging.Under 800 ℃ heat is not peeling.Under 900 ℃ gas corrosion resistant ability.

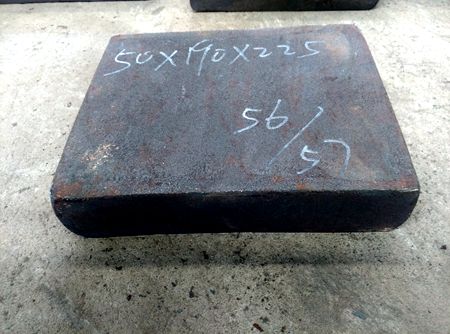

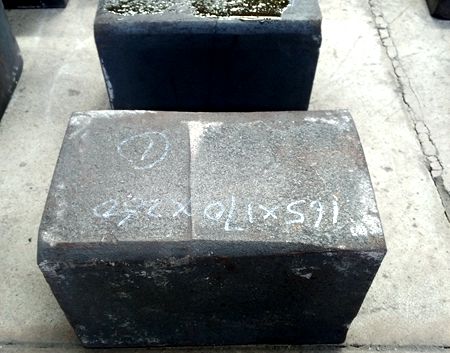

4Cr14Ni14W2Mo steel is often used in the manufacture of engine inlet and outlet valves, and steam and gas pipeline.

4Cr14Ni14W2Mo steel can be used to manufacture the titanium alloy creep into mold, highly corrosive glass forming core used in mold and die casting mould, etc.

4Cr14Ni14W2Mo join W, Mo element in steel is mainly in order to form carbide, take the C elements in steel, avoid C element and element Cr form carbides and reduce the Cr element content, so as to improve the electrode potential of steel, steel corrosion resistance and oxidation resistance.High temperature solid solution treatment is not soluble in W, Mo element of carbides in the grain boundary pinning effect, can prevent the austenitic grain size grew up, have the effect of refining grain, can contribute to the improvement of the tenacity of steel.Solid solution treatment, all elements of Cr, Ni and a small amount of W, Mo elements dissolve in austenite, solid solution strengthening austenite.W, Mo element when high temperature aging treatment of carbide precipitation from austenite and a small amount of Cr element of carbide precipitation from austenite, also with not dissolve of W, Mo, elements of the carbide, improve the strength, hardness and wear resistance of steel.

As W, Mo element of carbide precipitation from austenite, need high temperature heating and experience a longer time of heat preservation, so the 4Cr14Ni14W2Mo steel has high thermal stability.Under 650 ℃ has the good mechanical properties.During 600 ~ 800 ℃, easy for strongly reinforced by aging.Under 800 ℃ heat is not peeling.Under 900 ℃ gas corrosion resistant ability.

4Cr14Ni14W2Mo steel is often used in the manufacture of engine inlet and outlet valves, and steam and gas pipeline.

4Cr14Ni14W2Mo steel can be used to manufacture the titanium alloy creep into mold, highly corrosive glass forming core used in mold and die casting mould, etc.