The steel is a widely used international air cooling hardening cold work die steel.Approved by electric furnace smelting and the electroslag solubility, high purity, better toughness, uniform organization, has good high temperature strength, toughness and resistance to high temperature fatigue performance, can withstand the temperature shock.

High hardness, high wear resistant uniform eutectic carbides, good toughness, not easy craze, > 62 HRC hardness after quenching.At 525 ℃ nitriding processing time for 20 h/h/h, 60 ammoniation layer depth of 0.25 mm / 0. 30 mm / 0. 35 mm, the surface hardness is 1250 hv,At 570 ℃ nitriding processing time is 2 h, nitriding depth 10 ~ 20 microns, the surface hardness is 950 hv.

JIS SKD-11 Enquiry | Print this page

JIS SKD-11 Details

JIS SKD-11 Standard Download

SKD-11 Datasheet

JIS SKD-11| Category | Type | Grade | Designations |

|---|---|---|---|

| Grades | Tool Die Steels | SKD-11 | Japan - JIS , G 4404 (2006) - Alloy tool steels |

| Elements | Min.(≥) | Max.(≤) | Similar | Remarks |

|---|---|---|---|---|

| C | 1.4 | 1.6 | ||

| Si | - | 0.4 | ||

| Mn | - | 0.6 | ||

| P | - | 0.03 | ||

| S | - | 0.03 | ||

| Cr | 11 | 13 | ||

| Mo | 0.8 | 1.2 | ||

| V | 0.2 | 0.5 |

| Proof strength Rp0.2 (MPa) |

Tensile strength Rm (MPa) |

Impact energy KV (J) |

Elongation at fracture A (%) |

Reduction in cross section on fracture Z (%) |

As-Heat-Treated Condition | Brinell hardness (HBW) |

|---|---|---|---|---|---|---|

| 782 (≥) | 456 (≥) | 11 | 42 | 32 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 143 |

| Property | Density kg/dm3 |

Temperature T °C/F |

Specific heat J / kgK |

Thermal conductivity W/mK |

Electric resistance µΩ·cm |

Modulus of elasticity kN/mm2 |

Expansion rate |

|---|---|---|---|---|---|---|---|

| 312 (≥) | 762 (≥) | 33 | 33 | 41 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 444 | |

| Temp. °C/°F |

Creep strain limit (10000h) (Rp1,0) N/mm2 |

Creep rupture strength (10000h) (Rp1,0) N/mm2 |

|||||

| 846 | 226 | 319 |

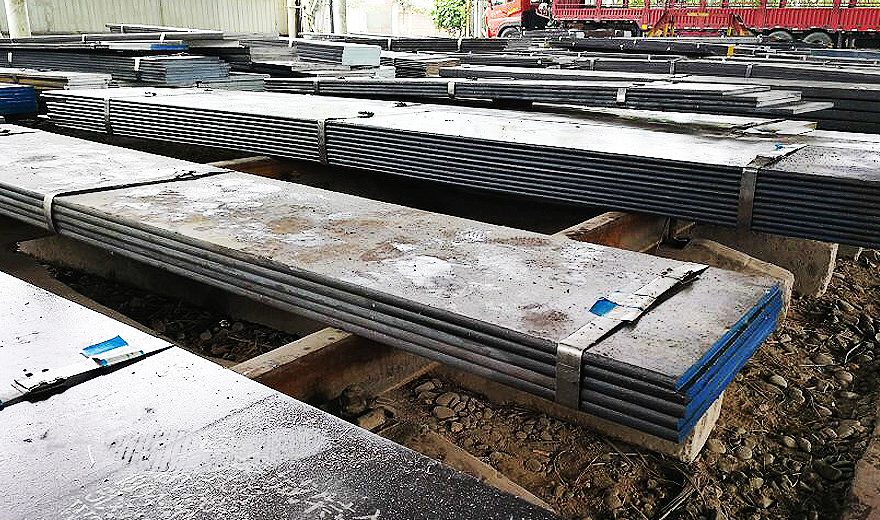

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

| Grade | Standard | Country | Application |

|---|---|---|---|

| D3 | ASTM | USA | Cold-Work Tool Steel |

| X165CrMoV12 | DIN | Germany | High alloyed CrMoV steel for cutting tool and cold work tool steel |

| 1.2601 | DIN | Germany | High alloyed CrMoV steel for cutting tool and cold work tool steel |

| SKD-11 | JIS | Japan | Mainly used for cold working mold: gauge, die for thread rolling, cutting tool for metal, forming roll, die for press. |

| SS 2310 | SS | Sweden | Cold work die steel, steel hardenability, quenching tempering hardness, wear resistance, strength are higher than the Cr12.Shape is complex, |

| X12M | GOST | Russia | Cold work die steel, steel hardenability, quenching tempering hardness, wear resistance, strength are higher than the Cr12.Shape is complex, |

| X160CrMoV12 / Z160CDV12 | AFNOR | France | Cold working alloy tool steels |

Relevant products

SKD-11 Equivalent Grade Stock

| Steel grade | Dimension | Shape | Unit | Quantity | Delivery state | Query |

|---|---|---|---|---|---|---|

| Cr12MoV | 12-160(T)*310-610(W)*L | Plate or Sheet | Tons | 12.38 | Hot-Rolled+Annealed+black | Enquiry |

| 1.2601 | 12-160(T)*310-610(W)*L | Plate or Sheet | Tons | 11.22 | Hot-Rolled+Annealed+black | Enquiry |

| SkD-11 Round Bar Stock | Φ30-Φ350 | Round Bar | Kgs | 3102 | Hot-Rolled+Annealed+black | Enquiry |