MP35N is an age hardenable Nickel-Cobalt base alloy that has a unique combination of properties - ultra high strength, toughness, ductility and outstanding corrosion resistance. MP35N resists corrosion in hydrogen sulphide, salt water and other chloride solutions. It also has excellent resistance to crevice and stress corrosion cracking in sea water and other hostile environments. Suitable where a high combination of strength, high modulus values and good corrosion resistance are required. Applications for this alloy also include medical devices and dental products.

Combination of high strength, ductility and good mechanical properties at ambient temperatures Excellent corrosion resistance in hydrogen sulphide Excellent resistance to crevice and stress corrosion cracking in sea water Age hardenable (Spring Temper only)

AMS MP35N Enquiry | Print this page

AMS MP35N Details

AMS MP35N Standard Download

MP35N Datasheet

AMS MP35N| Category | Type | Grade | Designations |

|---|---|---|---|

| Grades | Superalloys | MP35N | USA - AMS , AMS 5844 - AMS 5845 - ASTM F562 - ISO 15156-3(NACE MR 0175) - ISO 5832-6 - |

| Elements | Min.(≥) | Max.(≤) | Similar | Remarks |

|---|---|---|---|---|

| C | - | 0.025 | ||

| P | - | 0.015 | ||

| Si | - | 0.15 | ||

| Ni | 33.00 | 37.00 | ||

| Co | - | Bal | ||

| Mn | - | 0.15 | ||

| S | - | 0.01 | ||

| Cr | 19.00 | 21.00 | ||

| Mo | 9.00 | 10.50 | ||

| Ti | - | 1.00 | ||

| Fe | - | 1.00 |

| Proof strength Rp0.2 (MPa) |

Tensile strength Rm (MPa) |

Impact energy KV (J) |

Elongation at fracture A (%) |

Reduction in cross section on fracture Z (%) |

As-Heat-Treated Condition | Brinell hardness (HBW) |

|---|---|---|---|---|---|---|

| 198 (≥) | 336 (≥) | 11 | 42 | 13 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 434 |

| Property | Density kg/dm3 |

Temperature T °C/F |

Specific heat J / kgK |

Thermal conductivity W/mK |

Electric resistance µΩ·cm |

Modulus of elasticity kN/mm2 |

Expansion rate |

|---|---|---|---|---|---|---|---|

| 911 (≥) | 299 (≥) | 11 | 42 | 44 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 431 | |

| Temp. °C/°F |

Creep strain limit (10000h) (Rp1,0) N/mm2 |

Creep rupture strength (10000h) (Rp1,0) N/mm2 |

|||||

| 353 | 419 | 799 |

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

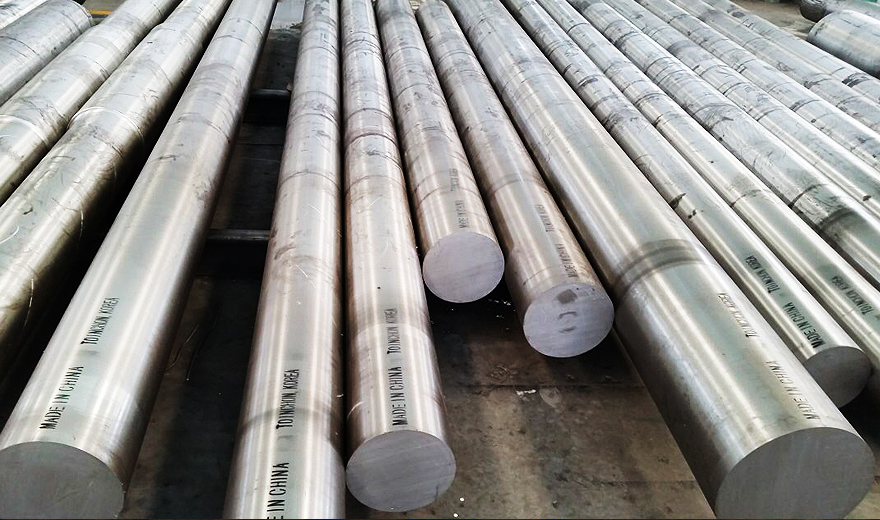

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

| Grade | Standard | Country | Application |

|---|---|---|---|

| MP35N | AMS | USA | Medical Devices Marine Engineering |